Challenges and Opportunities for Pharma Manufacturing and Logistics in the Face of COVID-19

Ada Palmadottir recently participated in PMPS's 2021 FlyPharma panel discussion titled, Challenges and Opportunities for Pharma Manufacturing and Logistics in the Face of COVID-19.

I recently participated in PMPS's 2021 FlyPharma panel discussion titled, Challenges and Opportunities for Pharma Manufacturing and Logistics in the Face of COVID-19. Below are my key takeaways from the event:

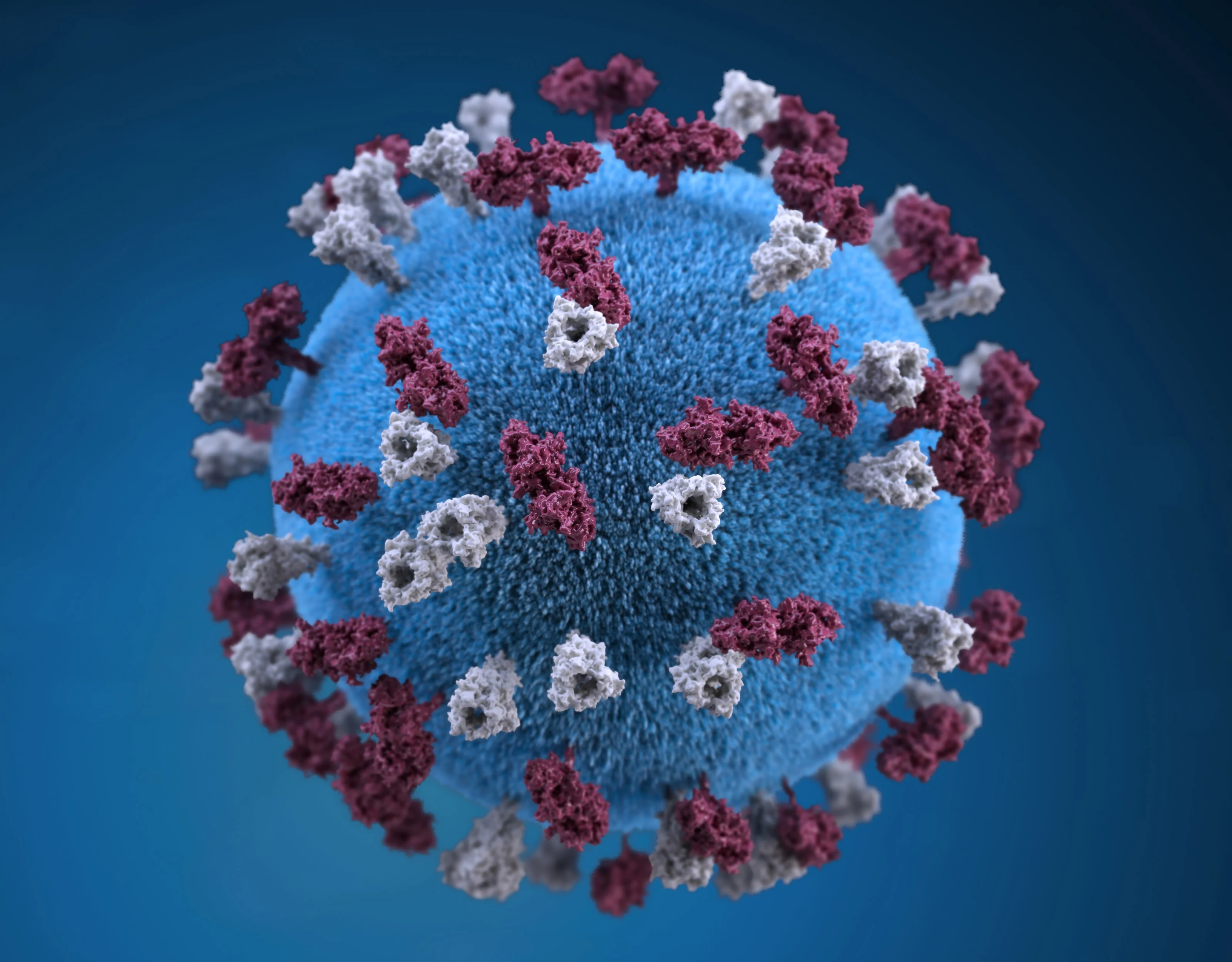

The COVID-19 pandemic has changed everyone’s lives and the way we conduct business. The early days of the crisis were chaotic as we forged into unknown territory. Supplier bottlenecks and shortages, delays at ports of entry, an increased risk of damage and theft, and reduced labor due to illness all led to industry disruption. All those challenges also left many organizations without the visibility to determine where issues might arise or be able to prevent future ones from occurring. Technology became a critical tool to keep “business as usual” in the new normal of COVID-19.

And as the pandemic spread, pharmaceutical manufacturers raced to develop a viable vaccine and produce it in large enough quantities to help stop the growing number of cases. The swiftness of the vaccine development led to the need to transport the products in extremely low temperatures to keep them viable. These events—the hurdles of pandemic itself and the vaccine manufacturing and distribution—coalesced to form supply chain challenges unlike anyone has experienced.

While the industry has changed drastically, it has also found ways to overcome these unprecedented challenges, thanks in large part to increased collaboration, having an efficient control tower, and implementing effective technological solutions. The right technology, data, and a comprehensive control tower can help the pharma cold chain make smarter decisions and prevent lost loads, which is especially critical in the COVID-19 vaccine distribution. Our control tower allows companies to have one central repository for all of the data and provides a single source of truth.

Some questions pharmaceutical supply chain stakeholders should consider are:

- Do I own all of my data, or am I receiving it from external stakeholders?

- Does my data allow me to make preventative decisions?

- Can I benchmark the performance of my third-party services suppliers?

- Is my data descriptive or predictive?

- Do I have end-to-end supply chain visibility?

- Does my control tower offer only visibility, or does it improve my responsiveness and collaboration?

The value of data does not lie in its quantity but in its quality and what can be done with it. Utilizing the right tools and technology to gain understanding will enable control. Control leads to improvement, and a focus on continuous improvement will identify new opportunities and uncover potential risks. Supply chain leaders need to analyze data, determine root causes, investigate alternatives, and understand their impact and opportunity costs—all to derive insights that drive action.

This article is taken from Pharmaceutical Manufacturing and Packing Sourcer COVID-19 Supplement February 2021, pages 4-7. © Samedan Ltd.

About Ada Palmadottir

Ada Palmadottir is Business Development Director at Controlant. With more than 20 years of experience in pharmacy, management, and technology, Ada has extensive international experience in sales, operations, and marketing, specifically in the areas of product, vertical alliance sales, and partnerships related to pharmaceutical products. She is a licensed and experienced pharmacist and earned a Master of Pharmacy from the University of Iceland and a Master of Business Administration from the Norwegian School of Management in Oslo. Ada has been working with Controlant for the last eight years.